Company Details

Company Details

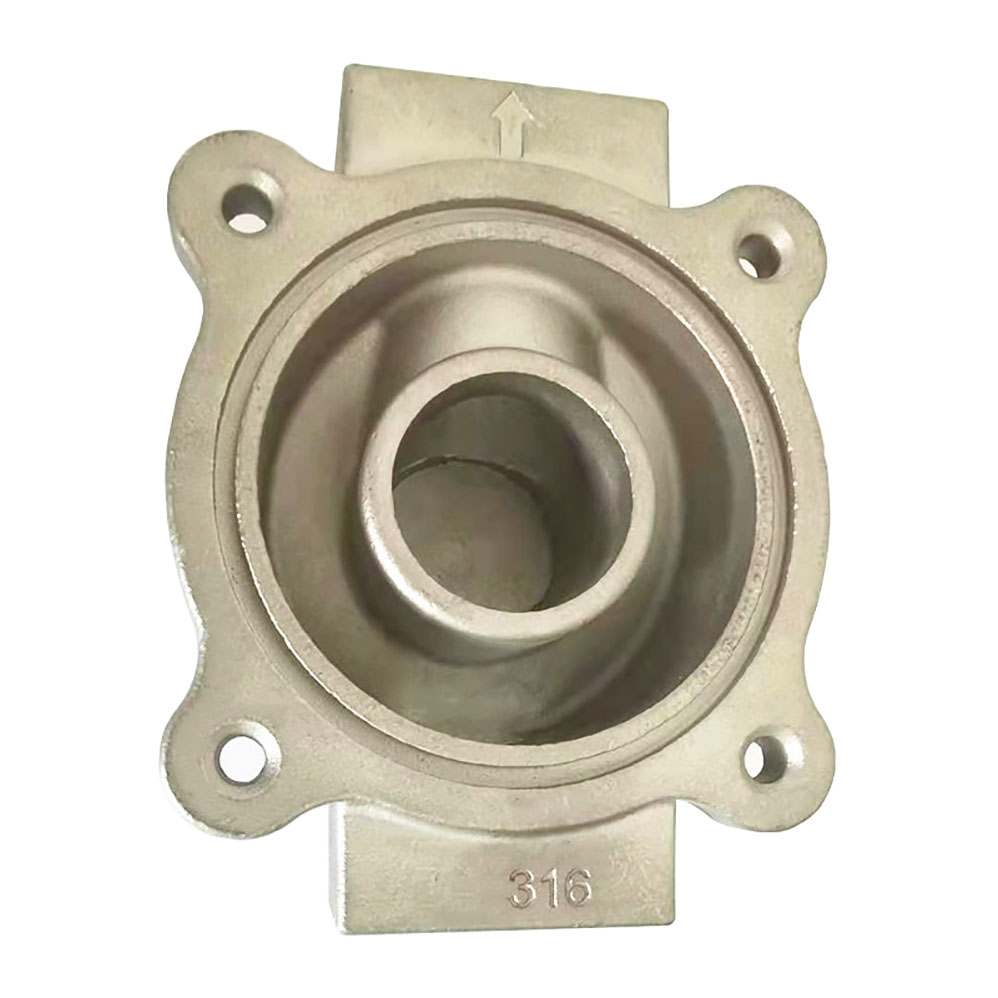

We made a lot of Investment Casting Parts, as well as Die Casting Mold Development. But what is the process? Casting molding generally does not apply pressure, the strength of the equipment and mold is not high, the size of the product is small, the internal stress in the product is low. Therefore, the production investment is less, can be made of good performance of large parts, but the production cycle is longer, after molding must be machined. On the basis of traditional casting, the methods of casting, inlay casting, Pressure Casting, rotary casting and centrifugal casting are derived.

⑤ Centrifugal casting: A quantity of liquid material is injected into the mould which rotates at a high speed and can be heated, and the material is distributed to the inner wall of the mould cavity by centrifugal force. After physical or chemical action, the product is solidified into tubular or hollow tubular products (see figure [centrifugal casting]). Monomer casting nylon parts can also be formed by centrifugal casting.

Product Range: CNC Machining , CNC Machining Parts , Precision Machining, CNC Milling , CNC Turning Parts , Machining, Forging, Forging Parts, Investment Casting, Die Casting , Casting Parts, Sheet Metal Fabrication, Product Assembly Service...

Tel: +86-769-81582278

Mobile: +86 189 2921 5001 (WhatsApp/WeChat)

Email: sandy@sczyltd.com

Address: No. 1906, Vanke Center, Changqing South Road, Chang` An Town, Dong Guan City, Guangdong Province, PR China 523850

Author:

Ms. Sandy

Phone/WhatsApp:

August 26, 2022

July 28, 2022

December 01, 2021

SCZY LTD is one of the leading manufacturers for forging parts. We have Aluminum Forging Parts, steel forging parts, Closed Die Forging Parts, etc. Precision plastic forming is one of the main...

In precision casting, what materials are generally used? We usually make Carbon Steel Casting, Stainless Steel Casting, Specialty Alloy Casting,etc. So we can use stainless steel, carbon steel, alloy...

The difference between forging and casting lies in 5 points: different production and processing methods, different external words, different output and price, different materials, and different...

Lost wax casting, now known as Investment Casting, is a casting process with little or no cutting. It is an excellent process technology in the foundry industry and its application is very extensive....

Email to this supplier

Author:

Ms. Sandy

Phone/WhatsApp:

August 26, 2022

July 28, 2022

December 01, 2021